Manufacturers choose Printed Dry Erase, a MyWhiteBoards brand, to craft heavy duty whiteboards that stay pristine, even in a rugged factory setting. It’s no surprise why Lean whiteboards are so popular; because they are proven to eliminate waste and streamline operations. Here are the types of Lean Manufacturing whiteboards that are favored among manufacturers.

What is Lean Manufacturing?

Lean Manufacturing describes a method of operations that aims to execute a frictionless production process by cutting down on waste. Waste is defined by any action or object that does not add value to the bottom line. Sakichi Toyoda, founder of Toyota, the Japanese car manufacturer, is considered the father of Kaizen methodology and more specifically the “5 whys,” which seeks to get the the bottom of every issue that arises.

Whether you are honing in on Lean, 6 Sigma, Kanban, JIT, Kaizen, Agile, etc., the common denominator is the pursuit of continuous improvement.

“If you always do what you’ve always done, you’ll always get what you’ve always got.” ~Henry Ford

Lean Manufacturing Whiteboard

These Lean Manufacturing Whiteboard, shown below, make gaps, mistakes, interruptions, and other wasteful actions stand out. Physical displays like whiteboards in high traffic areas are proven to increase success, because they act as visual reminders, which are 20% more effective than aural reminders.

The Value Stream Map

In a market economy, the organization the best at efficiency and effectiveness will come out on top. A Value Stream Map is a popular manufacturing board because it provides a “big picture” view on the entire supply chain and it can help a production manager trace problems back to the root cause by showing the transfer of both goods and information. Value Stream Maps can help your production team implement “Just in Time Manufacturing” by tracking batches in the supply chain. Data can be taken from this daily rundown and added to a KPI table, enabling information transparency across any time frame. You can make your own version of this board here at our website.

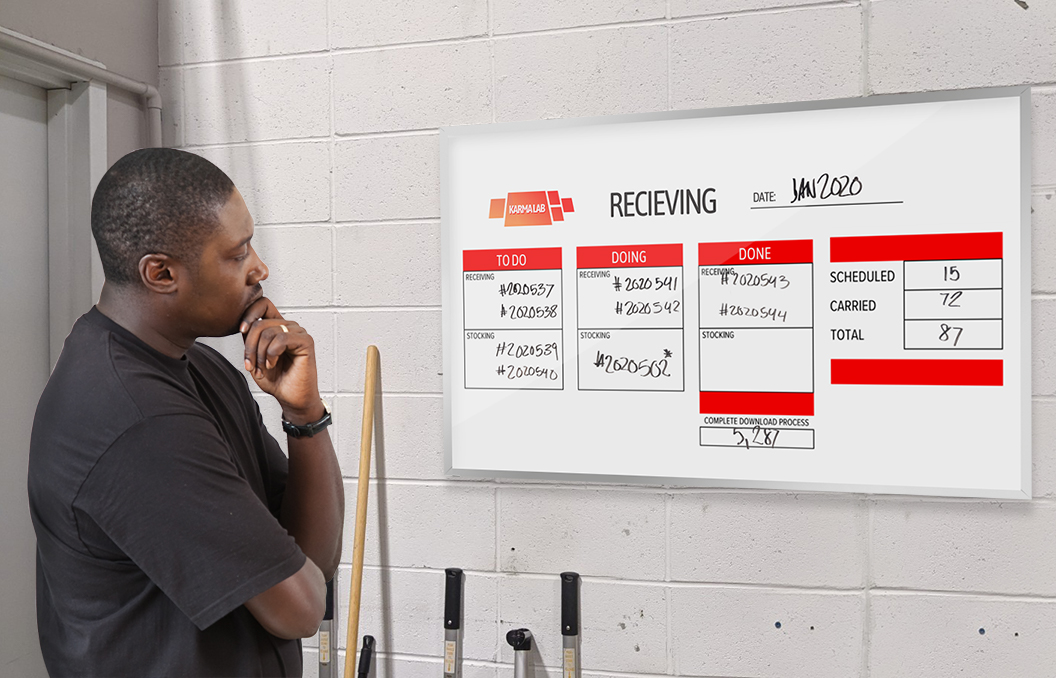

The Classic Kanban Board

A Kanban board is used to identify bottlenecks that need attention. This is one of the most common project management visuals because it’s simple, it’s production focused, and it highlights potential issues before they arise. Teams that use a physical Kanban board achieve a steadier workflow and less interruptions. Get your company Kanban Board here.

The Gantt Chart

When launching a new project or product, a Gantt chart visualizes a timeline that features overlapping tasks. A Gantt chart is the recommended tool for sprints or projects that need to be completed on a tight schedule. The overall goal is to decrease time waiting which is considered “waste” according to lean manufacturing, and to maximize a small amount of time. You can get your Gantt chart printed on a whiteboard here!

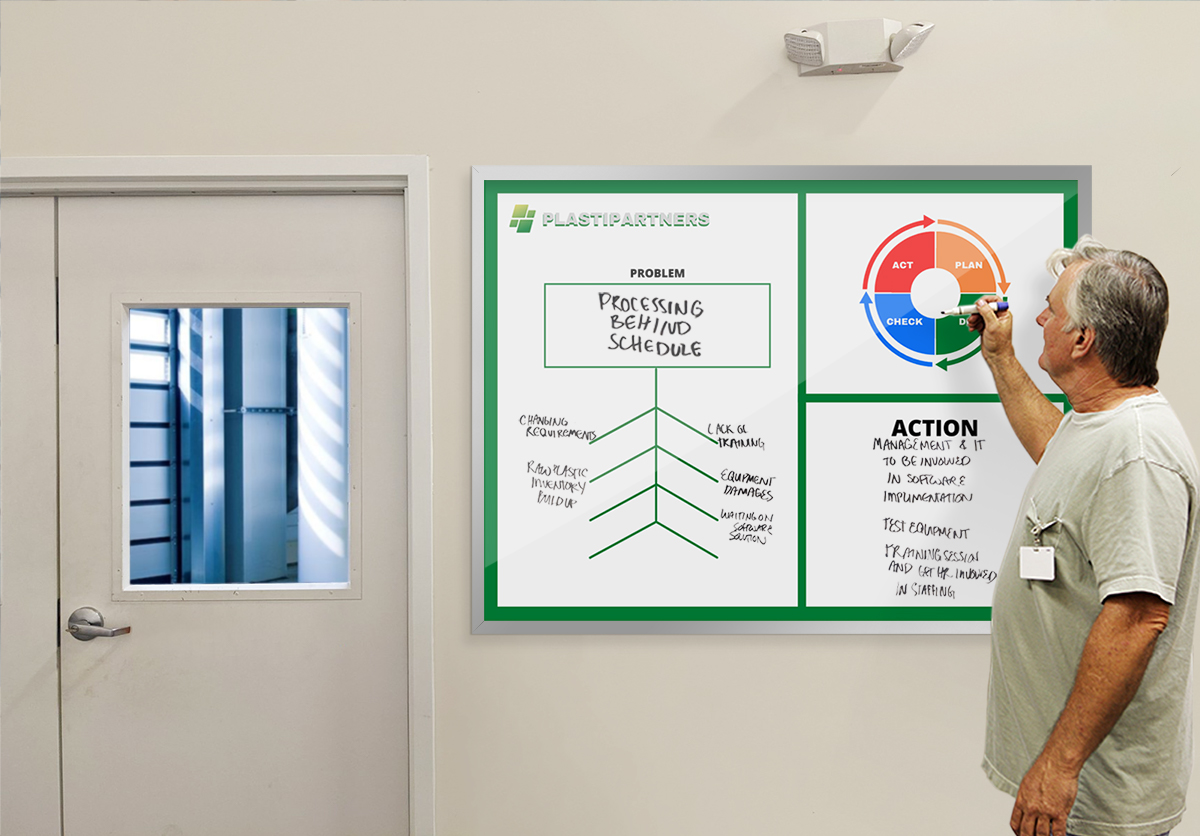

The Root Cause or Fishbone Diagram

The root cause diagram or fishbone diagram is a manufacturing tool used to break down production problems to their root causes. It answers the question, “why?” It’s a tool that lean teams use when implementing organizational structural changes, floor layout changes, or any other change that impacts the day-to-day operations. This example is paired with the Plan, Do, Check, Act visual that provides a basis for continuous improvement. Making a space for action items not only holds the team accountable, but also decreases decision-making fatigue. Let the experts at Printed Dry Erase design, print and construct your Fishbone Board here.

Master a Lean Manufacturing Whiteboard Layout

It's much easier to achieve a lean layout with visuals, specifically a magnetic dry erase board that you can customize to any square footage. These magnetic floorplans allow you to reimagine and rearrange easily with cuttable square foot magnets! The cuttable magnets have a ghost grid that lines up with each square foot of your warehouse, office building or house. Label them with dry erase markers and reuse them over and over again.

|

|

Gallery of Lean Manufacturing Whiteboards

Measuring success is a critical part of approaching Lean Methodology. Production and Operation Managers invest in “Lean Boards,” to display many other critical success factors like Lead Time, Production Volume, Right First Time, Equipment Effectiveness, Days Since Last Accident, Defect Density and more. It all depends on your organizational goals.

https://www.youtube.com/watch?v=cISU8xEZJu0&ab_channel=KatieatOptima

For questions or orders, call 866–366–1500 or visit our website.